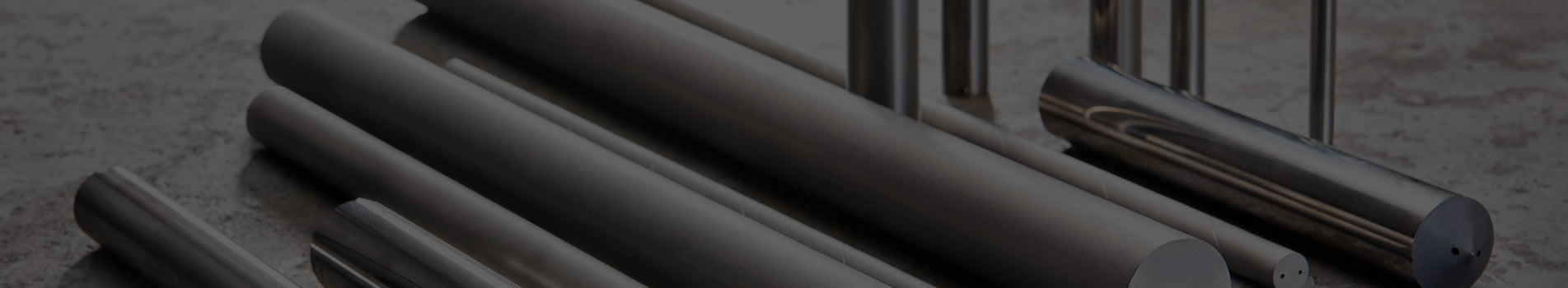

What are Tungsten Carbide Rods?

Solid tungsten carbide rods are widely used for high-quality solid carbide tools such as milling cutters, end-mills, drills or reamers. Specialized in tungsten carbide round bars, with an outstanding product line of solid carbide rod, we manufacture and stock unground and ground carbide rods for you. h6 polished chamfered carbide rods are most popular.

Matrial Grade:

GRADE | GD12 | GD14 | GD12 | |

ISO | K20-K30 | K40-K50 | K05 | |

Cobalt | % | 10 | 12 | 6 |

WC | % | 90 | 88 | 94 |

Grain Size | um | 0.6 | 0.5 | 0.8 |

Density | g/cm3 | 14.5 | 14.1 | 14.9 |

Vicker | Kg/mm2 | 1600 | 1680 | 1510 |

Rockwell | ISO3738 | 91.8 | 92.5 | 91.5 |

T.R.S | N/mm2 | 4000 | 4000 | 3400 |

Below is Rough Blank Solid Carbide Rods Specification:

Type (Dia. x Length) | Tol. Of Diameter | Tol. Of Length |

Dia.0.50~12 x 330 | +0.20~+0.45 | 0~+5.0 |

Dia.12.5~20 x 330 | +0.30~+0.60 | 0~+5.0 |

Dia.21.0~42 x 330 | +0.50~+0.80 | 0~+5.0 |

Length to be chosen:

300mm or 310mm or 330mm or Cut to the length as requested

Solid Carbide Rods in Unground

Solid Carbide Rods in Polished h6 or other requested

Sintering HIP.

The advanced computer-controlled HIP furnaces are applied to provide more pressure during the sintering process in order to get denser structure.

Powder Excellent.

Thanks to our deep cooperation with Germany H.C.Starck, we use the best powder for carbide rod in the world for all our standard grades for carbide rod manufacturing.

Production Fast.

Three different compaction methods, including extrusion, automatic press, and cold isostatic press are used for the maximum efficiency of carbide rod manufacturing.

Special Methods

|  |  | ||

| Extrusion is the most popular method of producing carbide rods. It is a very practical way to manufacture long carbide rods like 330mm.310mm and 500mm, etc. However, its time-consuming drying process is the weakness that we have to pay attention to. | Automatic pressing is the most effective ways to press short sizes like 6*50,10*75,16*100, etc. It can save cost from cutting carbide rods and it doesn’t need time to dry. So the lead time is faster than extrusion. On the other hand, long rods cannot be manufactured by this method. | Cold isostatic press(CIP) is the latest technology of making carbide rods. Because it can make long bars like 400mm but it doesn’t require wax like extrusion, so it doesn’t need time to dry, either. This is the best option when making big diameters like 30mm and 40mm. | ||

|  |  | ||

| Unground Rod | Polished Rods | Polished Chamfered Rods |

Our Rods are Widely Used For Below Applications:

|  |  |  |

| Drill Bits | End Mill | Milling Cutter | Reamers |

Zhuzhou Zhongge Cemented Carbide Co., Ltd.

AdăugaNr. 1099, Pearl River North Road, Tianyuan District, Zhuzhou, Hunan

TRIMITE-NE POSTA

DREPTURI DE AUTOR :Zhuzhou Zhongge Cemented Carbide Co., Ltd. Sitemap XML Privacy policy