Cold Heading

What is Cold Heading

Cold heading manufacturing is a multi-step process used to form metal parts at room

temperature. Unlike other metal fabrication processes, hammers and dies are used at

a high speed to form the metal without heating the material.

A large coil of wire is fed into a blank and pulled through a drawing machine. The

drawing machine compresses the material to the desired diameter. It then passes into

the cold heading machine.

Inside the cold heading machine, the blank is hit between a die and a punch block,

pushing the material into the die to create the desired shape.

We use two separate techniques for forcing the material into the die. With the upset

method, the punch block forces the metal out of the die to produce a head larger

than the initial blank.

The extrusion technique includes two methods, forward and backward extrusion. With

forward extrusion, the cavity of the two dies is smaller compared to the diameter of

the wire, which creates compression. With backward extrusion, the metal is forced

backward through a punch to create a hole or cavity.

Cold heading is commonly used for creating custom screws, bolts, and other custom

fasteners out of round metal stock.

When should you choose cold heading for your parts?

Cold forming comes with advantages and disadvantages compared to other machining

processes, such as screw machining.

While using a screw machine may eliminate the need for dies, cold forming requires

dies to set the head shapes, which increases the lead time and initial cost.

However, cold heading includes many benefits:

• Less waste

• Faster production

• Stronger parts

• Reduced costs

Using cold heading for your parts reduces material waste. More of the material is

utilized during the cold forming process. This limits scrap and overall costs.

Inside the cold heading machine, the blank is hit between a die and a punch block,

pushing the material into the die to create the desired shape.

We use two separate techniques for forcing the material into the die. With the upset

method, the punch block forces the metal out of the die to produce a head larger

than the initial blank.

The extrusion technique includes two methods, forward and backward extrusion. With

forward extrusion, the cavity of the two dies is smaller compared to the diameter of

the wire, which creates compression. With backward extrusion, the metal is forced

backward through a punch to create a hole or cavity.

Cold heading is commonly used for creating custom screws, bolts, and other custom

fasteners out of round metal stock.

When should you choose cold heading for your parts?

Cold forming comes with advantages and disadvantages compared to other machining

processes, such as screw machining.

While using a screw machine may eliminate the need for dies, cold forming requires

dies to set the head shapes, which increases the lead time and initial cost.

However, cold heading includes many benefits:

• Less waste

• Faster production

• Stronger parts

• Reduced costs

Using cold heading for your parts reduces material waste. More of the material is

utilized during the cold forming process. This limits scrap and overall costs.

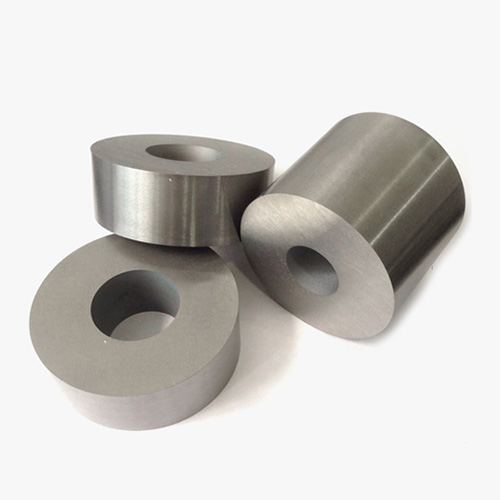

Goode Carbide produce as-sintered tungsten carbide die inserts and blanks for use in

hot and cold heading die tooling and forming tool applications. Inserts are made to

order and can be supplied in different tungsten carbide material grades with up to a

25% Cobalt binder to meet our customers’ specific requirements to produce numerous

bolts, screws and special fixings, in a variety of materials. We produce the die

inserts and blanks in the as-sintered condition with the specific overall dimensions

and special features our customers request ready for them to produce finished ground

tooling.

Hot and Cold Heading Die Inserts

Cut-off Die Inserts

Forging Dies

Ejector Pins

Punches

Our factory is equipped to make tungsten carbide heading die inserts and forging

dies blanks in all sizes up to a maximum outside diameter of 250mm. We maintain good

supplies of our tungsten carbide raw material in stock and aim to supply the

as-sintered die inserts and blanks on a short delivery lead time as required.

Our factory is equipped to make tungsten carbide heading die inserts and forging

dies blanks in all sizes up to a maximum outside diameter of 250mm. We maintain good

supplies of our tungsten carbide raw material in stock and aim to supply the

as-sintered die inserts and blanks on a short delivery lead time as required. Talk

to a Goode Carbide expert about your specific application requirements.

Tungsten Carbide Heading Dies

Goode Carbide produce as-sintered tungsten carbide die inserts and blanks for use in

hot and cold heading die tooling and forming tool applications. Inserts are made to

order and can be supplied in different tungsten carbide material grades with up to a

25% Cobalt binder to meet our customers’ specific requirements to produce numerous

bolts, screws and special fixings, in a variety of materials. We produce the die

inserts and blanks in the as-sintered condition with the specific overall dimensions

and special features our customers request ready for them to produce finished ground

tooling.

Hot and Cold Heading Die Inserts

Cut-off Die Inserts

Forging Dies

Ejector Pins

Punches

Our factory is equipped to make tungsten carbide heading die inserts and forging

dies blanks in all sizes up to a maximum outside diameter of 250mm. We maintain good

supplies of our tungsten carbide raw material in stock and aim to supply the

as-sintered die inserts and blanks on a short delivery lead time as required.

Applications:

Tungsten carbide pellets are widely used in cold heading dies and punching dies for manufacturing nuts, screw caps, bolts, cans and many other products.

Material Grade:

Unlike other carbide manufacturers, we produce our powders from the raw materials, this guarantees the highest quality tungsten carbide throughout the process and maximizes performance for the end user

|

Grade |

Density g/cm3 |

T.R.S Mpa |

Hardness HRA |

Properties & Applications |

|

GD10 |

13.5 |

3000 |

83.50 |

Good wear resistance and bending strength. It is often preferrd by nut forming dies and high impact-resistant dies. |

|

GD11 |

14.4 |

2420 |

88.50 |

Forming or stamping dies for metal powders and nonmetal powders. |

|

GD15 |

14.0 |

2500 |

87.50 |

It is suitable for drawing steel tubes and rods under high compression ratio, manufactuing upsetting, punching and forging tools under large stress. |

|

GD20 |

13.50 |

2800 |

85,50 |

It is suitable for manufacturing punching dies for watch parts, leaf spring of musical instruments, battery jars, small sized steel balls, screws, screw caps, etc. |

|

GD32 |

13.90 |

2750 |

85.50 |

It is suitable for impact-resistant forging dies. |

|

GD36 |

13.70 |

2800 |

84.50 |

It is suitable for impact-resistant forging dies, hot-forging dies and finishing rollers. |

|

GD40 |

13.50 |

2850 |

83.50 |

It is suitable for wear resistant or impact resistant dies. |

|

GD50 |

13.30 |

2900 |

83.0 |

It is suitable for nut forming dies and high impact-resistant dies.

|

|

GD60 |

13.10 |

2950 |

82.50 |

It is suitable for stainless screw dies and semifinishing rollers. |

|

GD80 |

13.10 |

3050 |

83.40 |

It is suitable for screw cap forming dies with high strength ( highest impact-resistant forging dies). |

Specifications:

Including but not limited to the following types.

|

|

Dinension |

|

||

|

d |

D |

L |

||

|

BDP00710- |

0.7 |

10 |

12.0-20.0 |

M1 |

|

BDP01010- |

1.0 |

10 |

12.0-20.0 |

M1.5-M2 |

|

BDP01013- |

1.0 |

13 |

15.0-40.0 |

M1.5-M2 |

|

BDP01213- |

1.2 |

13 |

15.0-40.0 |

M1.5-M2 |

|

BDP01510- |

1.5 |

10 |

12.0-25.0 |

M2 |

|

BDP01516- |

1.5 |

16 |

15.0-45.0 |

M2 |

|

BDP01813- |

1.8 |

13 |

12.0-45.0 |

M2.5 |

|

BDP01816- |

1.8 |

16 |

20.0-45.0 |

M2.5 |

|

BDP02113- |

2.1 |

13 |

15.0-30.0 |

M3 |

|

BDP02116- |

2.1 |

16 |

25.0-45.0 |

M3 |

|

BDP02316- |

2.3 |

16 |

15.0-45.0 |

M3 |

|

BDP02522- |

2.5 |

22 |

20.0-60.0 |

M3 |

|

BDP02813- |

2.8 |

13 |

15.0-30.0 |

M4 |

|

BDP02816- |

2.8 |

16 |

25.0-40.0 |

M4 |

|

BDP02818- |

2.8 |

18 |

20.0-50.0 |

M4 |

|

BDP02820- |

2.8 |

20 |

20.0-50.0 |

M4 |

|

BDP02822- |

2.8 |

22 |

20.0-60.0 |

M4 |

|

BDP02825- |

2.8 |

25 |

20.0-60.0 |

M4 |

|

BDP03216- |

3.2 |

16 |

15.0-45.0 |

M4 |

|

BDP03218- |

3.2 |

18 |

15.0-50.0 |

M4 |

|

BDP03616- |

3.6 |

16 |

20.0-50.0 |

M5 |

|

BDP03618- |

3.6 |

18 |

20.0-60.0 |

M5 |

|

BDP03822- |

3.8 |

22 |

20.0-40.0 |

M5 |

|

BDP03830- |

3.8 |

30 |

50.0-60.0 |

M5 |